Written by: Chelly Mei Tanpoco and Audrei Anne Ybanez

A common durability issue observed in coastal concrete infrastructure is the corrosion of the steel reinforcement or rebar. This problem primarily occurs due to the ingress of chloride ions from seawater and the carbonation of the concrete cover caused by atmospheric carbon dioxide. Both processes break down the passive protective film on the rebar, leaving it vulnerable to corrosion.

Once corrosion begins, rust forms and expands, occupying a greater volume than the original steel. This expansion leads to cracking, spalling, and delamination of the concrete.

The rate of corrosion is influenced by several factors, including:

- The aggressiveness of the surrounding environment

- The thickness of the concrete cover surrounding the rebar

- Concrete Mix Design used

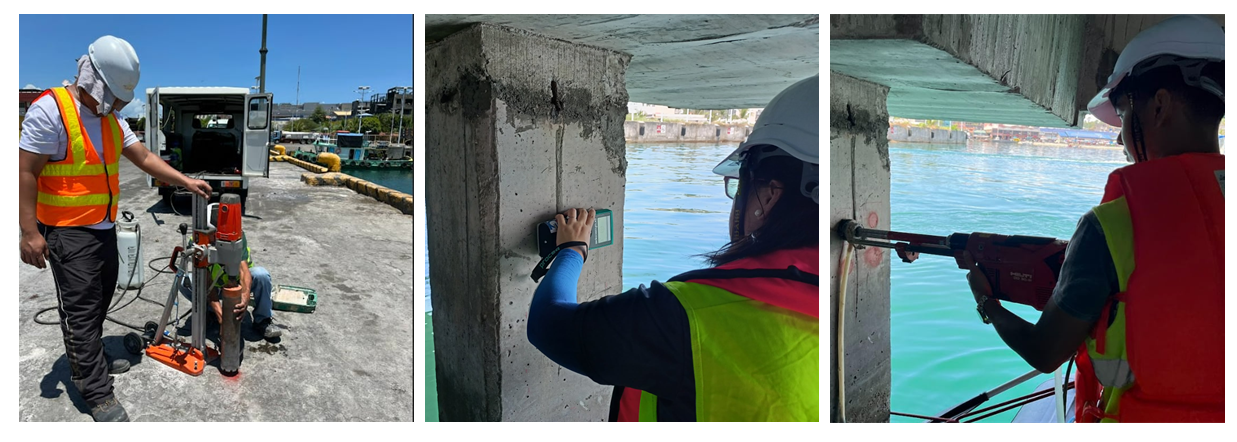

To investigate how cover thickness and mix design affect corrosion rates, the research team from the ExCoN: Effects of Extreme Weather Conditions on Coastal Concrete Project is conducting a laboratory experiment that accelerates rebar corrosion using locally available concrete raw materials.

The experiment is conducted based on the impressed current method which uses an external DC power source to induce and accelerate the corrosion process. In this setup, the concrete specimens with embedded rebar act as the anode, and a sacrificial metal (such as copper) will serve as the cathode. The specimens are submerged in a saline solution to simulate coastal conditions.

Faraday’s law is then used to relate the measured current to the rate of electron consumption. Further analysis using Concrete Petrography will then be conducted to understand reactions and deteriorations present in a microscopic scale.

Enhancing Port and Seawall Infrastructure Resilience through Durable Concrete Design

In coastal port infrastructure, one of the key challenges is the corrosion of steel reinforcement in concrete due to exposure to seawater and harsh marine environments. Addressing this issue is vital for maintaining the structural integrity and longevity of critical port assets.

Ongoing research, such as the ExCoN Project, highlights how factors like concrete cover thickness and mix design directly impact corrosion rates. By understanding and optimizing these design parameters, engineers can significantly improve the durability of concrete structures in ports and seawalls.

This directly supports resilience by reducing maintenance needs, minimizing downtime, and ensuring infrastructure can withstand extreme weather, rising sea levels, and other coastal hazards. Durable and well-designed port infrastructure not only lowers long-term costs but also ensures continued functionality during and after disruptive events safeguarding trade, economic stability, and community lifelines.