Posted by: EMSCP-LAB and Hazard Assessment Team NOAH Center

The Department of Public Works and Highways – Bureau of Research and Standards (DPWH-BRS) has officially approved a local standard adopting the use of concrete petrography. BRS undertakes research into innovative technologies to identify appropriate standards for the improvement of DPWH projects. The formulation and approval of the new standard underwent a thorough review and evaluation for two years. This was made possible through the collaborative efforts between the Department of Science and Technology – Philippine Council for Industry, Energy, and Emerging Technology Research and Development, DPWH-BRS, University of the Philippines National Institute of Geological Sciences (UP NIGS), and the UP Resilience Institute (UPRI).

The new local standard on concrete petrography is largely based on ASTM C856 – Standard Practice for Petrographic Examination of Hardened Concrete. Significant technical findings from over six years of research on the evaluation of almost 1000 Philippine concrete cores and assessment of local concrete raw materials are integrated into the local standard.

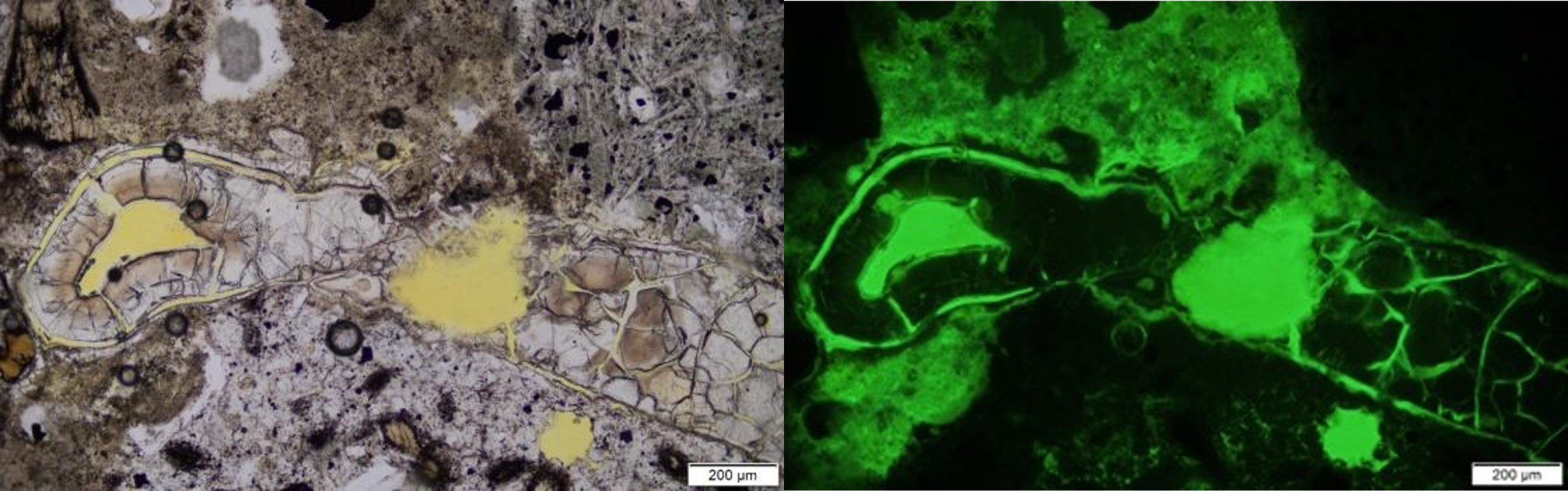

Concrete petrography is the gold standard in other countries for both forensic investigation and quality control of concrete and concrete raw materials. Parameters such as the amount of air, degree of hydration, water-cement ratio, and the presence or potential for degradation can all be determined with the use of concrete petrography. In the Philippines, petrographic examination aims to complement conventional physical test methods employed in the construction industry to provide a complete story of the composition and current condition of concrete.

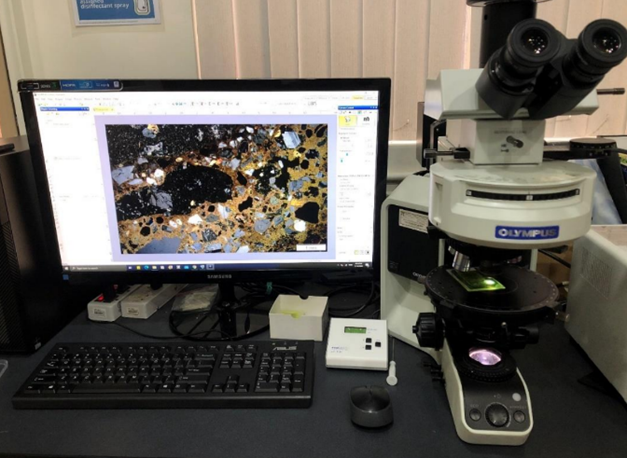

The first concrete petrography laboratory in the Philippines was established by the Earth Materials Science Laboratory (EMS-CPLab) in 2017 at UP NIGS. Since then, the EMS-CPLab has trained over 100 geologists and engineers on basic concrete petrography. As a result, DPWH-BRS in 2021 set up its own fully-functioning concrete petrography laboratory.

UPRI, in its goal of promoting resilience building, spearheads the implementation of the DOST-GIA funded project “Effects of Extreme Weather Conditions on Coastal Concrete Structures in the Philippines: Determining Appropriate Concrete Cover”. This project combines the use of concrete petrography to assess the current condition of coastal concrete, and materials testing to develop optimal concrete mix designs. The optimized concrete cover mix designs will be used in different microclimates in the Philippines. This research aligns with the mission of UPRI, to empower local communities through multidisciplinary actions toward resilience. By integrating concrete petrography into local construction practices, UPRI’s vision of a resilient built environment is one step closer.

The adoption of the local standard will help civil engineers and other stakeholders to make use of the results generated using concrete petrography. UPRI and EMS-CPLab extend its gratitude to all who supported this undertaking.

Stakeholders wishing to access the new standard may contact ems.concretelab@nigs.upd.edu.ph